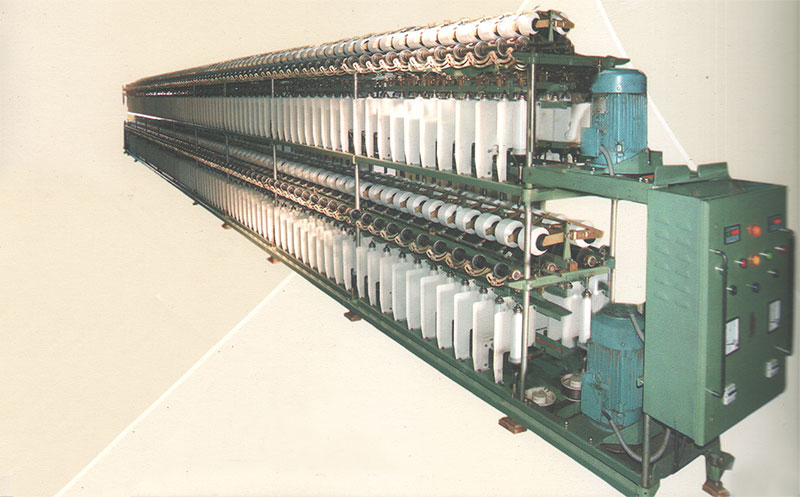

Two For One Twister

Outstanding Features

| Precise Spindle speed Both spindle and boister are precisely processed by our own equipments with high performance, and then go through the strict quality inspection procedures, so that they can remarkably improve the quality of twisting while guaranteeing their perfect performance even at high speed. |

| Lass Noise and Improved Durability Not only is the bolster specially designed for precise processing to minimize its noise, but also durability is remarkably improved by guaranteeing Less vibration on the basis of strict analysis on mechanical vibration. |

| Belt Tension Controller The motor base is equipped with a belt tension controller,-so that the damage to spindle and bolster resulting from high tension can be prevented, and an exact driving of spindle can be also guaranteed by automatically keep tension even, regardless of belt flexibility. |

| Convenient Workability The height of this machine is nest suited for convenient workability, the loading and unloading of cyinder are simple, and a new type of cradle of cradle is applied to be available for reduction of working time. |

Technical Details

Change of Technical Structure in Traverse CAM

Even winding type by the fixed distance of traverse feeding, Iengthning the life of CAM by lower tension of traverse spring.

Lower-Noise Spindle

• Making the noise against air minimize by the desing of spindle

• Exact concentric degree and lengthening of life of spindle by the non-bolt type

More Easier Operation of Gearbox

• Attachment of the automatic oil suply device

• Management of tools and prevention of loos of spare gear

• Maintenance of clear gear box and lengthenance of life of gear

| Two For One Twister TECHNICAL SPECIFICATION | |||

|---|---|---|---|

| MODEL | ATE90U | ATE90B | ATE70U |

| Frame | Double deck on both sides | Double deck on both sides | Double deck on both sides |

| Supply Package | Nylon or polyester pirn 100 mm dia "270-320 mm long | Nylon or polyester pirn 80 mm dia *270 long | Nylon or polyester pirn 80 mm dia *270 long |

| Take-up package | Conical and cheese | Cylinder | Cylinder and cheese |

| Take-up capacity (max) | 1000gm | 1000gm | 750gm |

| Denier Range | 30-300d | 30-300d | 30-300d |

| Drive | Motor 7.5kw,4p*2 set Star delta slow start device S & Z twists swtchable | Motor 7.5kw,4p*2 set Star delta slow start device S & Z twists swtchable | Motor 7.5kw,4p*2 set Star delta slow start device S & Z twists swtchable |

| Spindle speed | 7,000-18,000 r.p.m. | 7,000-18,000 r.p.m. | 7,000-18,000 r.p.m. |

| Motor pulley | 3 pcs. For 12,000, 14,000 16,000 r.p.m. As the standard supply | 3 pcs. For 12,000, 14,000 16,000 r.p.m. As the standard supply | 3 pcs. For 12,000, 14,000 16,000 r.p.m. As the standard supply |

| Twist range | 400-4,000T/M yarn speed shall be set at Ma.40-n/min | 400-4,000T/M yarn speed shall be set at Ma.40-n/xmin | 400-4,000T/M yarn speed shall be set at Ma.40-n/min |

| Spindle belt | Endless belt with nylon core | Endless belt with nylon core | Endless belt with nylon core |

| Spindle pitch | 220 mm | 220 mm | 175 mm |

| Traverse length | 165 mm | 165 mm | 128 mm |

| Tension | Ball tension device | Ball tension device | Ball tension device |

| Feed roller | V-groove plate made of M. S. Hard Chrome | V-groove plate made of M. S. Hard Chrome | V-groove plate made of M. S. Hard Chrome |

| Package form | Central G-Box | Central G-Box | Central G-Box |

| Take-np package setting | Spindle less cradle type | Spindle less cradle type | Spindle less cradle type |

| Attachments | • Yarn feed stop device at Yarn beakage | • Yarn feed stop device at Yarn beakage | • Yarn feed stop device at Yarn beakage |

| • Spindle revolution indicator. | • Spindle revolution indicator. | • Spindle revolution indicator. | |

| • Yarn length-meter. | • Yarn length-meter. | • Yarn length-meter. | |

| • Yarn speed-meter. | • Yarn speed-meter. | • Yarn speed-meter. | |

| • Operation hour-meter | |||

| Packing | Dismantled packing | Dismantled packing | Dismantled packing |

Outstanding Features